Robot operation involves mechanical movement and electronic component operation:

Therefore, timely maintenance and upkeep of the machine is crucial.

| Category | No. | Inspection Item | Inspection Method | Judgment Criteria | Result (Value) |

|---|---|---|---|---|---|

| Control | 1 | Appearance check (BOX, operation panel) | Visual | No scratches, dents, or dirt | |

| Control | 2 | Operation panel LCD screen | Visual | No display defects, no flickering | |

| Control | 3 | Operation panel buttons/switches | Press touch buttons | Screen response is smooth | |

| Control | 4 | Emergency stop switch (BOX, operation panel) | Press emergency stop | Motion stops (power OFF) | |

| Control | 5 | Earth leakage switch | Press leakage test button | Leakage mode appears (power OFF) | |

| Control | 6 | Internal BOX wiring | Visual check | No loose terminals/connectors, no insulation layer peeling | |

| Control | 7 | Cooling fan | Visual | Air intake or exhaust in specified direction | |

| Control | 8 | Alarm history check | Visual | No frequent unusual alarms; if frequent errors like grip failure, consult customer for advice |

| Category | No. | Inspection Item | Inspection Method | Judgment Criteria | Result (Value) |

|---|---|---|---|---|---|

| Mechanical | 1 | Compressed air | Visual | No excessive oil or moisture | |

| Mechanical | 2 | Vertical, horizontal, traverse axis mounting screws | Visual check marks | No deviation of marks | |

| Mechanical | 3 | LM guide rails and sliders of each axis drive | Visual | Rails lubricated, no fatigue damage, scratches, or oil stains; LM sliders not damaged | |

| Mechanical | 4 | Timing belts of each axis drive | Visual | No damage, serpentine pattern, or warping | |

| Mechanical | 5 | Operation sound of each axis drive | Listen | No abnormal noise or sluggish movement sound | |

| Mechanical | 6 | Wiring and piping of each axis | Visual | No breakage, deformation, or surface damage | |

| Mechanical | 7 | Cable carriers and communication wiring of each axis | Visual | No interference with other components | |

| Mechanical | 8 | Supply air pressure | Visual | Pressure gauge shows 0.5MPa; normal range | ( )MPa |

| Mechanical | 9 | Balance cylinder air pressure (ignore if no balance cylinder) | Visual | Main arm up/down (standard, adjusted value); Sub arm up/down (standard, adjusted value) (fill in specific MPa) | ( )MPa |

| Mechanical | 10 | Vacuum generation unit suction check (filter oil contamination) | Visual, clean | Vacuum pressure gauge needle: when suction closed ≤-50KPa; when suction open shows "0" | ( )MPa |

| Mechanical | 11 | Cylinders, solenoid valves, joints | Listen | No air leakage | |

| Mechanical | 12 | Shock absorbers of each axis (ignore if no shock absorber) | Visual | No oil leakage | |

| Mechanical | 13 | Components (pressure reducing valve) | Visual | No oil stains, blockage, or water accumulation | |

| Mechanical | 14 | Silencer | Visual | No oil stains or blockage | |

| Mechanical | 15 | Vibration and cushioning when each axis stops | Visual | Shaking and impact within range that does not affect other components | |

| Mechanical | 16 | Robot and frame mounting screw fixation | Visual check | Spring washers not damaged or loose |

| Category | No. | Inspection Item | Inspection Method | Judgment Criteria | Result (Value) |

|---|---|---|---|---|---|

| Others | 1 | Display plates, warning plates | Visual | No peeling or oil stains | |

| Others | 2 | Instruction manual | Check | - | |

| Others | 3 | 3S operation | Visual | - |

| No. | Precautions | Image |

|---|---|---|

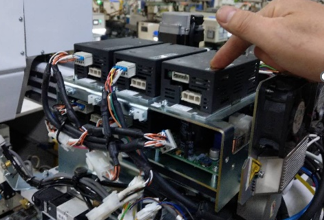

| 1 | Before maintenance, be sure to cut off the control box power, turn off the air switch, and wait ten minutes before operation. |

|

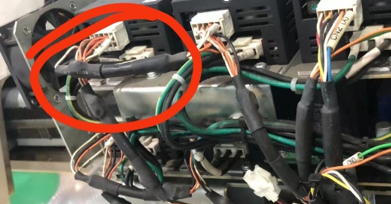

| 2 | When cleaning dust from electrical components in the control box, do not use compressed air with moisture to avoid damaging electrical components. |

|

| 3 | After cleaning, restore all protective covers of the machine. Do not work with covers open to prevent dust and moisture from entering and damaging the machine. |

|

| No. | Precautions |

|---|---|

| 1 | Must use company-specified lubricant (AFB-LF). The grease gun nozzle is custom-made by the company and must be ordered from the company. |

| 2 | Lubrication cycle should be adjusted according to actual molding cycle and operating rate, with a maximum interval not exceeding three months. |

| 3 | Long-term use without lubrication is prohibited, as it will cause damage to the robot's LM guide rails and sliders, and generate abnormal noise. |

| 4 | If abnormal noise occurred before guide rail lubrication and does not improve after lubrication, it indicates the guide rail and slider are defective and need timely repair. |

| 5 | When lubricating, observe if new grease overflows from the other side of the slider, then stop. Promptly clean residual oil stains on the guide rail (containing metal powder and deteriorated grease will damage components). |

| 6 | If problems occur during maintenance lubrication, contact the company's after-sales service department promptly. |

| 7 | Lubrication cycle is calculated based on 20 hours of production per day. |